High Temperature Filaments

Discover our High Temperature Ultrafuse® Filaments portfolio

With their wide spectrum of material performance advantages, the Ultrafuse High Temperature Materials can be successfully used in applications where other plastics, e.g. polyamide, polycarbonate, polyoxymethylene and polyalkylene terephthalates, fail to meet the performance specifications.

Ultrafuse® High Temperature Filaments portfolio

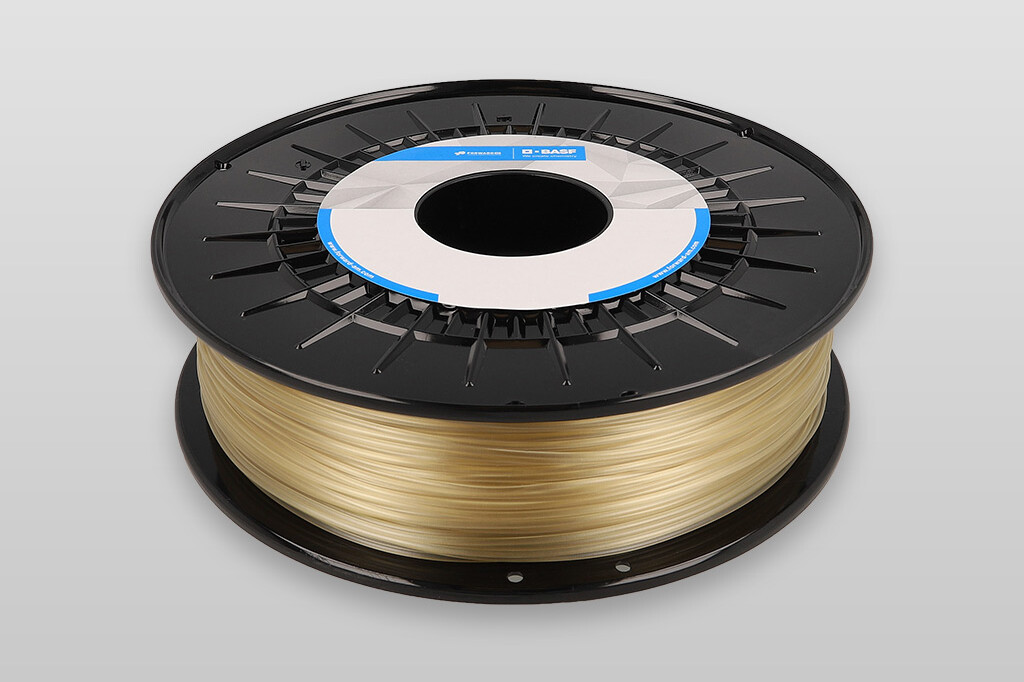

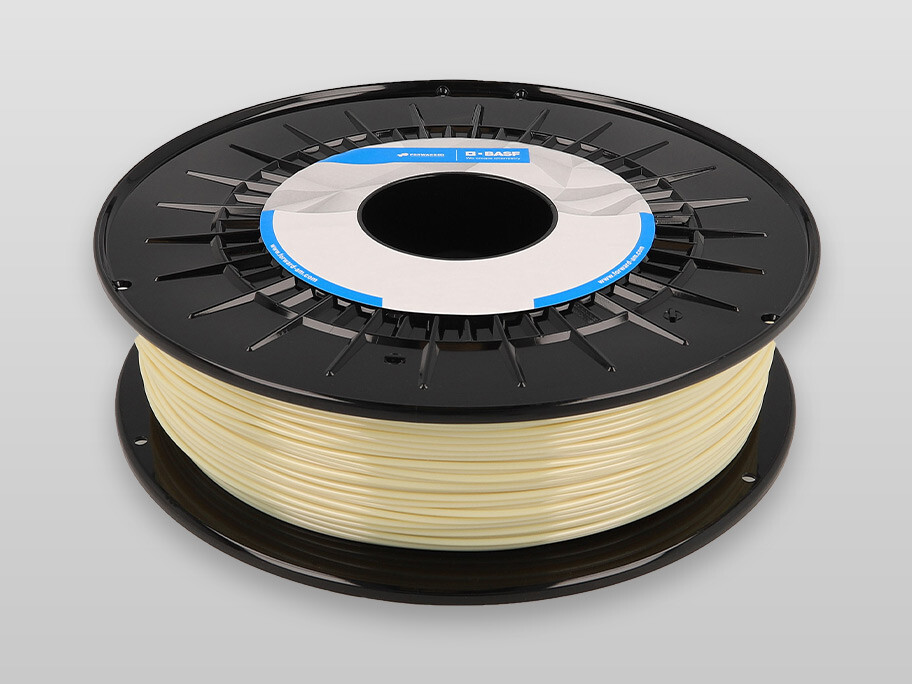

Ultrafuse® PPSU

PPSU our High-Temperature Ultrafuse® Filament

Benefits at a Glance

- Inherently flame retardant

- Short-term temperature resistance up to 220 °C

Next Steps

Get in touch

Do you have questions about our materials, technologies or services? Get in touch now!

Printing Profiles

We offer you multiple options to get print profiles based on each printer builder.

Work with Print Profiles